Contents

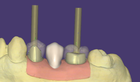

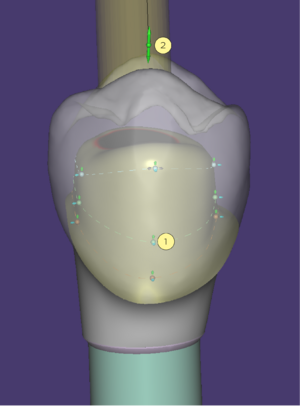

Control points

There are control points [1] on the abutment which can be moved inwards, outwards, up, and down to change the abutment's shape. Note that the software ensures that undercuts are avoided, and production-specific design restrictions are enforced. Therefore, there is - intentionally - some restriction in the movement, and moving one control point can cause another control point above or below to move as well.

With the green control point [2] between the arrows in the center of the abutment, you can adjust the overall abutment height.

| For a more complex shape, you can add additional control points on any line by holding the <CTRL> button pressed and clicking left on the dotted control line. When dragging control points, you can press <SHIFT> to apply the movement to the two adjacent control points on each side. To apply a movement to all control points of a dotted line, hold both <CTRL> . This is particularly useful to achieve your desired design quickly! Hold <CTRL> and left-click on the green arrow to flatten the abutment's top surface. |

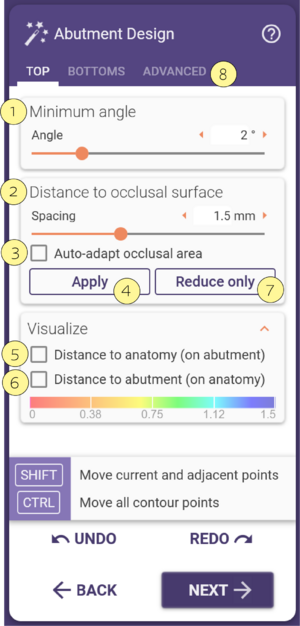

Wizard tab: Top

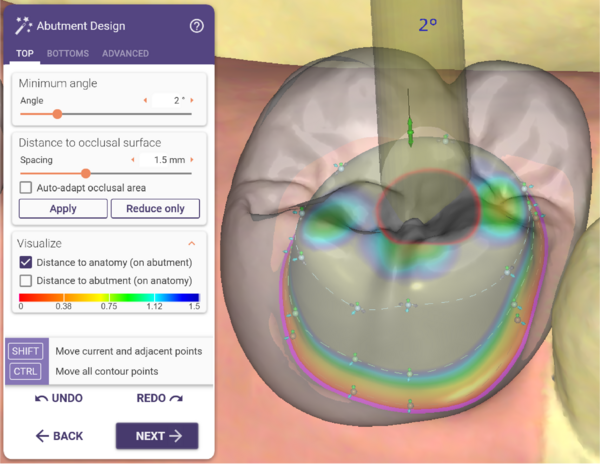

The slider [1] in the wizard window enforces a minimum draft angle of the abutment, and it doesn't allow the abutment to have undercuts. Lower values are easier to design.

It is also possible to tell the software to enforce a certain space between the anatomy and the abutment with the Spacing slider [2]. If Auto Adapt checkbox [3] is set, both the distance and the occlusal shape of the abutment are precisely offset from the chewing surface.

If a change to [1] or [2] is entered, these changes will only be applied if either the Apply [4] or the Reduce only [7] button is clicked. The Apply [4] button will both reduce and grow the shape in order to reach the desired distance values; the button Reduce only [7] will only shrink the abutment at parts where the distance to the anatomy is lower than the set value.

With activating the checkbox Distance to anatomy [5], you can visualize the distance of the anatomy to the abutment, the visualization is displayed on the abutment. The visualization is color-coded from red (low distance), to blue (high distance).

The highest value is set by the slider Spacing [2].

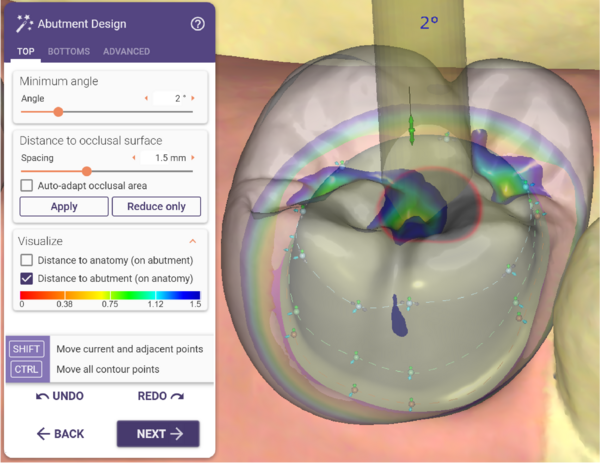

You can also have a measurement Distance to abutment [6] displayed on the anatomy.

Wizard tab: Bottom

Use this tab to correct your abutment bottom design, without going backward in the wizard. For details, see section "Generate abutment bottoms"

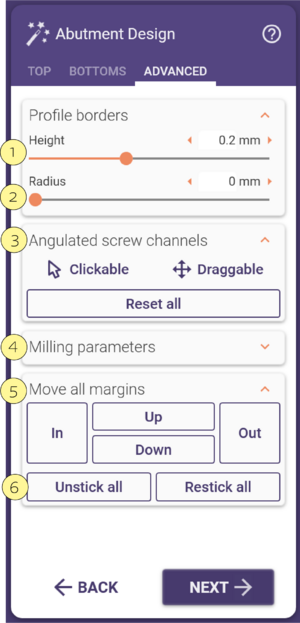

Wizard tab: Advanced

Use this tab to adjust the profile borders, angulate screw channels, set the milling parameters, and adjust the margins.

The slider Height [1] sets the minimum height of the abutment profile border.

The slider Radius [2] controls the round-off at the sharp edge of the border.

[5]: Allows you to move all points that define the border (abutment margin) at the same time, inwards, outwards, up or down.

[6]: These controls allow you to stick or unstick all of the border control points to the gingiva (tissue).

Angulated screw channels

Angulated screw channels [3] is possible, if the configuration of your exocad software, and the implant library used, allows this.

There are two possibilities to do it:

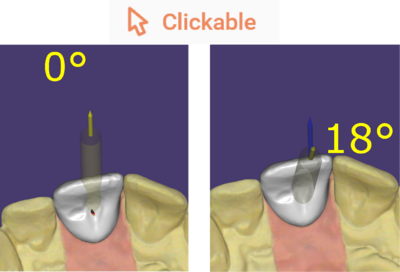

- Clickable

Click anatomic surface, pre-op or waxup scan to let the screw channel go through this point.

Hint: Hold CTRL and click to reset the previously manually defined angle.

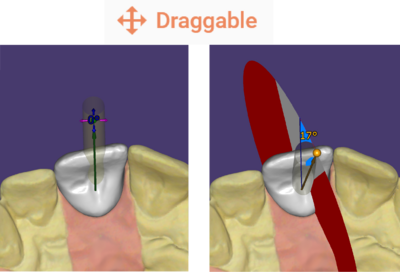

- Draggable

Define screw channel angle by dragging an arrow.

Holding CTRL and SHIFT restricts angle movement to the current angulation plane.

Holding CTRL and 'X' restricts angle movement to the implant analog plane.

Holding CTRL and 'I' snaps the angle to the nearest Integer value.

Holding CTRL, SHIFT and 'I' snaps the angle to intervals of 1°.

See our video tutorial for details.

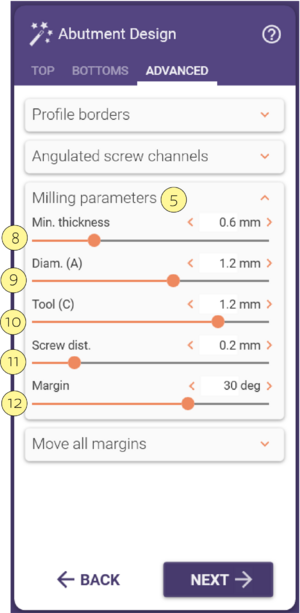

Expanding the Milling Parameters [5] control reveals the following:

- [8] Min thickness sets the minimum thickness of the abutment's axial walls.

- [9] Diam. can be used to set the diameter of the tool used to mill the abutment, also known as the tool compensation. You should add at least 0.2mm to the smallest tool size.

- [10] Tool sets the diameter of the tool used to mill the suprastructure (crown or coping).

- [11] Screw Distance keeps a minimum distance of the abutment to the screw channel. The control points can't be set closer to the screw channel than this value.

- [12] Margin is the minimum angle of the margin of the abutment.

| You even get the best fitting between abutment and suprastructure if you mill both parts at the same time. This is why we fully consider parameters [9] and [10] during the design. If these parameters are set to zero, you will get more freedom in design, but you have the problem that the sharp edges at the top of the abutment cannot be milled because of the tool diameter. You need to adjust these values to match your milling system. |