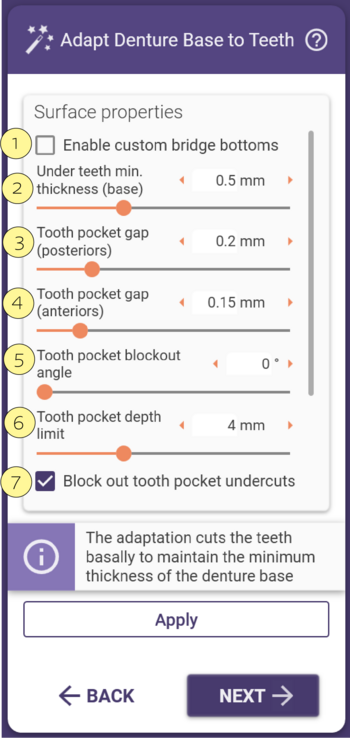

Adapting the Denture Base to the Teeth

In the final Wizard step, the basal surfaces of the teeth are adapted to the alveolar ridge. The denture base is adapted to the model and tooth sockets are generated for the denture teeth.

- Activate [1] to generate optimal bridge bottoms, with minimal tooth pocket depth.

- The Under teeth min. thickness (base) [2] refers to the minimum thickness to be considered for the base below the teeth, which is typically much lower than the overall minimum thickness requirement. Warning: The previously generated or free-formed prosthetic base must already have the required thickness since the adaptation step cannot generate additional thickness. It only tries to preserve the minimum thickness if possible.

- The Tooth pocket gap (posteriors) [3]widens the tooth pockets of posterior teeth by this offset e.g. to have spacing for the glue and compensation for the production process. Note that further settings (e.g. possibly activated milling compensation) might cause much more widening than this value.

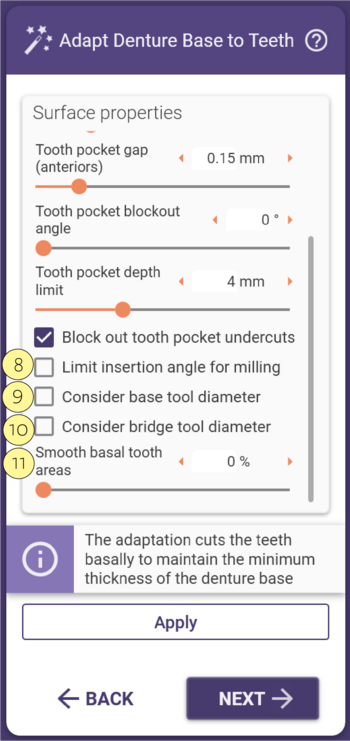

- The Tooth pocket gap (anteriors) [4]widens the tooth pockets of anterior teeth by this offset e.g. to have spacing for the glue and compensation for the production process. Note that further settings (e.g. possibly activated milling compensation) might cause much more widening than this value.

- The Tooth pocket blockout angle [5] blocks out the tooth pocket side walls with this blockout angle. Increasing the value can help with inserting into very deep tooth pockets, but might leave larger unexpected gap spaces at the top of the tooth pockets.

- The Tooth pocket depth limit [6] is an approximate threshold for the maximum intrusion of the teeth into the designed gingiva base using the insertion direction of the tooth (or bridge) and potentially some special handling for anterior teeth. The smaller it is, the less deep the pocket will be.

- The Block out tooth pocket undercuts [7] widens tooth pockets in the base to avoid collisions with teeth due to possible undercuts in the tooth models. This is highly recommended when milling angle limitations are involved, or when the bottoms of the original tooth library might not be blocked out perfectly relative to its occlusal axis. This is also recommended when producing denture tooth bridges, to allow blocking out the bridge insertion directions.

- The Limit insertion angle for milling [8] widens tooth pockets in the base so that all tooth pockets can be milled with a 5-axis machine with the given angle limit relative to the insertion direction of the base. Note: It does not enforce the same insertion direction to all unless you set the insertion angle limit to 0°.In any case, in the case of denture bridge milling, each bridge will have a unified insertion direction (in standard software configurations), so it is not mandatory to enable this feature when 3D/printing bridges.

- Check the box Consider base tool diameter [9] if the denture base is milled to consider the tool diameter. The software will add additional spacing into the tooth pockets of the base where sharp edges of the teeth require the milling tool of the base to create additional spacing.

- Check the box Consider bridge tool diameter [10] if you are milling the denture tooth bridge.

Note: The larger the value, the more material might be removed from the base near the bridge connectors or between teeth. Therefore, a small milling tool should be used in the milling strategy for finishing the adjacent areas between teeth and the connector. Also keep in mind, that the milled bridge might look different than in the software, depending on the milling process. With correct parameters, the visually empty space that is generated by this diameter compensation corresponds to the rest material of the denture bridge milling process in adjacent bridge connector areas.

- The percentage applied of Smooth basal tooth areas [11] makes the edges rounder of the detected areas inside the gingiva and therefore allows easier production of tooth and base.

Note: The smoothing is only a heuristic percentage value and is independent of the milling radius.