The "Waxup" feature is used for digital copy milling. It has very specific requirements regarding input data. In particular, the scan of the waxup must only contain parts that are actually modeled in wax - it may not contain surfaces that actually belong to the stone model. In other words, if you look at model scan and waxup scan at the same time, absolutely no double surfaces may be present. Holes in the scan are permissible to a certain extent. However, the waxup scan must end in close proximity to the preparation margin. In the case of implant-based constructions, the waxup scan must reach all the way to the implant, or to the custom abutment respectively.

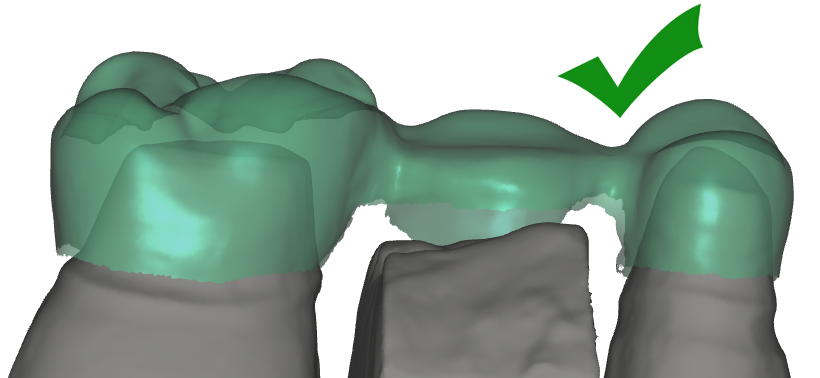

The following pictures illustrate the situation:

The picture above shows a correct data set for waxup processing. As you can see, the waxup scan starts above the preparation margin, and no double surfaces are present.

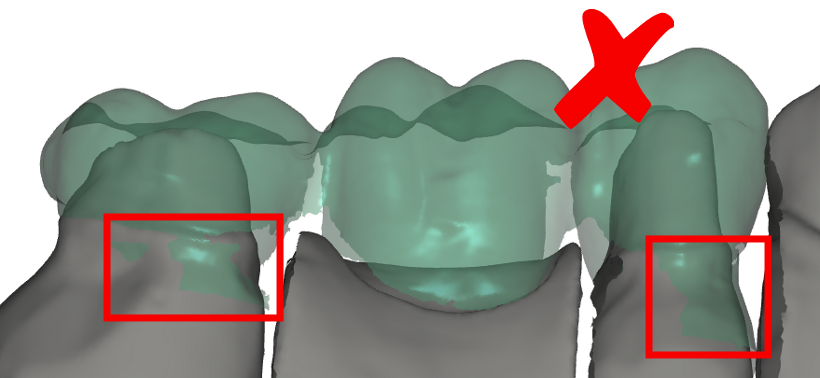

The above picture shows a data set not suitable for waxup processing. Marked in red are the problematic areas.

| The scanner software must ensure that input data is valid for waxup copy milling, by removing double surfaces. This is the reason why the "waxup" feature is available only with supported scanners (you cannot manually select an STL file - from a potentially unsupported scanner - to load as waxup scan). Please contact your scanner supplier for more information. |

| Instead of using the Waxup feature, you can also use "Situ scans" to achieve similar results. The above restrictions regarding scan data do not apply for the "Situ" feature. See "Understanding the difference between Situ and Waxup feature" for details. |