Contents

- 1 Info about exocad's material configuration

- 2 Zirconia

- 3 Zirconia Multilayer

- 4 Acrylic/PMMA

- 5 Wax

- 6 NP Metal

- 7 Titanium

- 8 NP Metal (Laser)

- 9 3D Print

- 10 Lithium Disilicate

- 11 Lithium Silicate

- 12 Composite

- 13 Hybrid ceramic

- 14 Glass ceramic

- 15 Feldspar

- 16 PEEK (only for certain removable restorations)

Info about exocad's material configuration

exocad DentalCAD's default configuration provides you a wide range of materials to chose from. In line with our 'open' approach, we do not mention brand names of the materials. In many cases, similar or equivalent materials within a certain class (e.g. Zirconia) are available from various manufacturers.

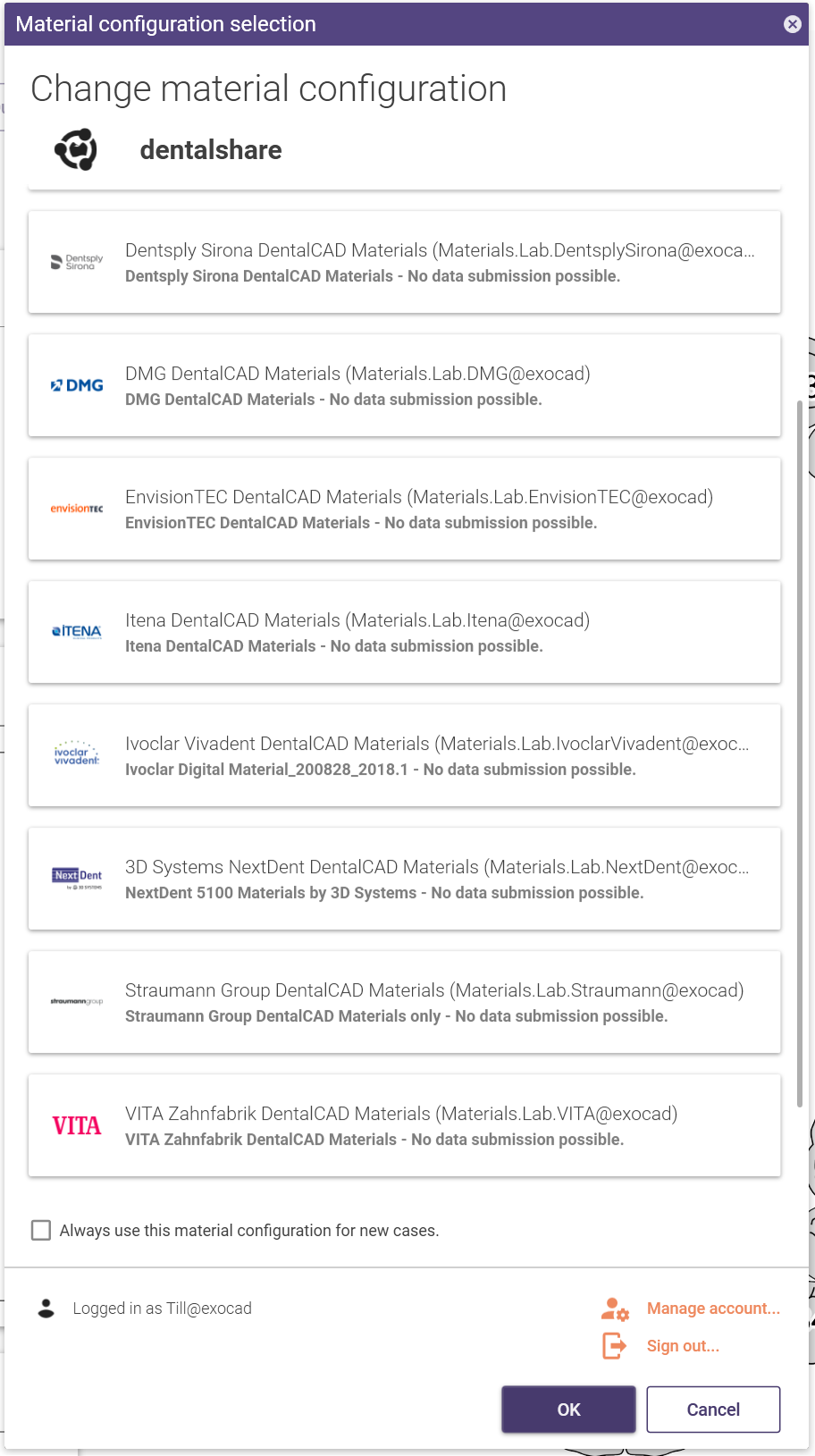

Getting access to more materials

In addition to the default materials, which are not brand specific, exocad provides a wide choice of brand-specific materials. By clicking on the button right of the "Indications & Materials" headline in DentalDB, you can get access to further material configurations.

These material files are stored on dentalshare, and will be updated automatically, so that you can always have access to the latest choice of materials.

You can find out more about dentalshare and how to set it up here, or (see video). Please note that not all exocad resellers grant access to dentalshare.

In addition, vendors of production equipment, or milling center services, may have their own dedicated material configuration for exocad, which differs from the default material configuration. These can either be provided through dentalshare as well, or as a separate file for manual installation. Please contact your vendor to obtain the correct configuration for your setup. The default configuration may not always give optimal results!

You can find out more about dentalshare and how to set it up here, or (see video). Please note that not all exocad resellers grant access to dentalshare.

In addition, vendors of production equipment, or milling center services, may have their own dedicated material configuration for exocad, which differs from the default material configuration. These can either be provided through dentalshare as well, or as a separate file for manual installation. Please contact your vendor to obtain the correct configuration for your setup. The default configuration may not always give optimal results!

Below is a list of our default materials with additional explanations.

Zirconia

Zirconium dioxide ceramic (ZrO2). Typically used for frameworks.

Zirconia Multilayer

Multi-layered shaded zirconium dioxide ceramic. If the In-CAD Nesting module is available, you can control the position of the shading relative to the tooth as part of the CAD workflow (see video). Multilayer/High Translucency Zirconia may need different CAM strategies or design parameters than 'regular' Zirconia. Contact your CAM vendor for details.

Acrylic/PMMA

Polymethylmethacrylate, which may come in tooth colored form (for temporary restorations), or in transparent (for Burnout & Cast technique)

Wax

Millable Wax, for Burnout & Cast technique. This material preset is parametrized for milling; if you wish to print Wax, use the generic "3D Print"material preset described below.

NP Metal

Non-Precious Metal. This is commonly used for Cobalt Chrome alloys. Note: Although technically, Titanium is also not a precious metal, we recommend to use the separate selection "Titanium" below.

Titanium

Titanium and Titanium alloys.

NP Metal (Laser)

Non-Precious Metal/Chrome Cobalt alloy, but produced by Selective Laser Melting - a production technique that requires different parameters/output data characteristics than milling.

3D Print

The various 3D printable materials typically have similar CAD parameters. A detailed material selection is available in the 3D printer software. You can take advantage of exoprint (see video) for a smooth, integrated workflow with many 3D printers.

Temporary Resin

A biocompatible resin used for fabricating provisional crowns, bridges, and restorations, offering short-term durability and esthetics.

Permanent Resin

A biocompatible, high-strength, wear-resistant resin designed for long-term restorations such as crowns, bridges, and hybrid dentures.

Castable Resin

A burnout resin used for fabricating patterns for casting metal frameworks, crowns, and partial dentures. It ensures clean burnout without residue, allowing precise metal or ceramic casting.

Splint Resin

A transparent, biocompatible resin specifically formulated for bite splints.

Lithium Disilicate

Lithium Disilicate-based glass ceramics, like Ivoclar's IPS e.max, or Hass Amber (where available).

Lithium Silicate

Lithium Silicate-based glass ceramics, like Vita Suprinity, Dentsply Celtra, Glidewell Obsidian.

Composite

Composites, such as VITA CADTemp, typically used for temporary restorations.

Hybrid ceramic

Hybrid ceramics, such as Vita Enamic, 3M Lava Ultimate, Shofu HC.

Glass ceramic

Glass ceramics that do not fall in any of the other categories. Mostly leucite-based glass ceramics, such as Ivoclar IPS Empress Restaurationen, or Hass Rosetta BM.

Feldspar

Feldspathic ceramics, including blocks such as VITABLOCS TriLuxe forte. If the In-CAD Nesting module is available, you can control the position of the shading relative to the tooth as part of the CAD workflow (see video). Not only layered blanks are supported, but also multi-colored blanks with more complex internal shapes, such as VITABLOCS RealLife.

PEEK (only for certain removable restorations)

Polyether ether ketone (PEEK) is a thermoplastic polymer that is commonly used for removables. PEEK is a High-Performance Plastic (HPP).

All trademarks mentioned here are the property of their respective owner